With its vast manufacturing base and diminishing workforce, China’s appetite for robots is rapidly increasing. One in four of the industrial robots sold in the world last year was in China, totalling 68,000 units, a 17 per cent increase over the previous year.[1]

With its vast manufacturing base and diminishing workforce, China’s appetite for robots is rapidly increasing. One in four of the industrial robots sold in the world last year was in China, totalling 68,000 units, a 17 per cent increase over the previous year.[1]

Being the manufacturing engine of China how are Guangdong’s factories reacting to the new industrial revolution? And what is the local government doing to support it? Nick Chen, Senior Project Manager at the Foshan National High Tech Industrial Development Zone (FHIDZ), takes a look.

The robotics industry and its market in China

China has been the largest industrial robot market in the world since 2013. Driven by market demand and government support, China’s robot industry is having to develop at an unprecedented rate in order to tackle the challenges presented by a dwindling workforce. It is estimated that by 2018, China’s robot market will account for over a third of the industrial robots installed worldwide.

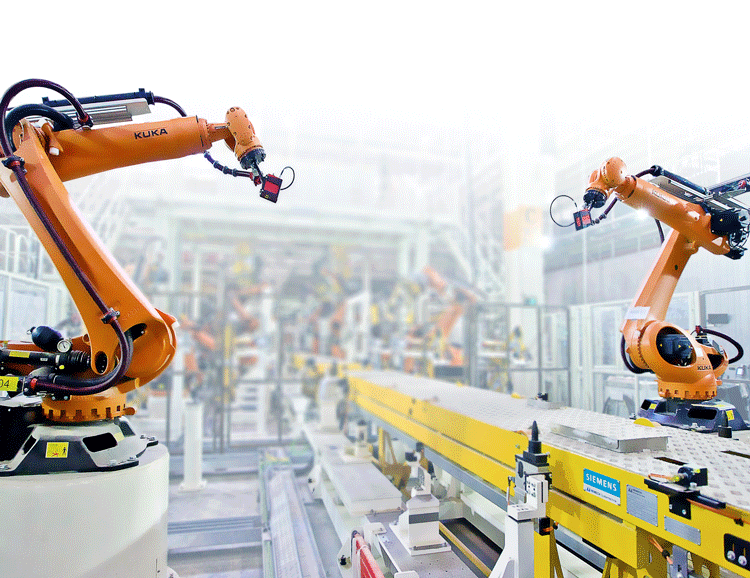

Due to early market entry, the robot market in China is currently dominated by foreign industry giants: ABB from Switzerland, FANUC and YASKAWA from Japan, and KUKA from Germany are all major players. In total, foreign-invested robotics companies account for over 70 per cent of the domestic industrial robot market.[2]

Meanwhile, domestic Chinese players have been somewhat lagging behind their international counterparts. They have historically faced problems due to a lack of the technological know-how required to produce high-quality key robot components, such as motor drives, gearboxes and controllers. As a result, many tended to specialise in the niche market – at present, domestic industrial robotics are mainly in the field of handling, loading and unloading, welding and brazing, assembly and disassembly, coating and sealing, processing and cleaning. Encouraged by a series of supporting policies, however, Chinese domestic players are beginning to catch up. There are over 800 companies involved in robotics manufacturing, and over 40 industrial parks focused in the robotics industry all over China.[3] The service scope of industrial robots has reached 36 national economic segments and 87 industrial sectors.[4]

The deployment of industrial robots is visible in many manufacturing companies in China, led by manufacturing clusters in some of South China’s cities, such as Foshan and Dongguan. As early as 2012, the FAW – Volkswagen Foshan factory, which is located in Foshan National High Tech Zone, has been recognised as the plant with the highest degree of automation in China. There are 884 robots in its welding workshop, which covers a total of 91,000 square metres, and the level of automation is up to 70 per cent.[5]

Entrepreneurs interested in robotics are naturally gathering in designated areas that have been selected and supported by the government for this purpose. For example, Foshan has built several clusters for the robotics industry under the policy of national and local government. In these robotics industry bases, Chinese entrepreneurs, scholars and researchers are being summoned to work on the R&D and application of robotics.

In the Guangdong Technology University CNC Equipment Cooperative Innovation Institute, around 50 enterprises have registered, 21 of which are related to the robotics industry.[6] The institute’s president, Yang Haidong, says that although most of the robotics companies in Foshan are SMEs, they all have their own unique, competitive advantages. According to Yang, Foshan robotics enterprises have four chief characteristics: first, they are specialised in different industrial segments of their own; second, they have strong R&D capability – almost all of the enterprises possess high-end research talent and professors, giving them a remarkable innovation advantage; third, they are very adaptive to the market and have strong expansion capability; finally, they share the concept of mutual development – they tend to collaborate with each other when working on major projects.[7]

The motivation to replace manual labour with robotics

The Chinese Government realised that the economic slowdown occurred, in part, due to its economic growth model leveraged by cheap labour. Since labour costs have exceeded 10 per cent of annual growth, many low-end manufacturing companies have been leaving China in favour of other cheaper Southeast Asian countries. In order to prevent the hollowing-out effect and the problems associated with the inevitable ageing workforce, the government has been strongly motivated to aggressively promote the application of robots in its manufacturing industry. It is expected by some that an economic model driven by the application of robots will lead to a new wave of steady and robust growth.

The main advantages of applying industrial robots are: 1) improved productivity; 2) an alleviation of labour costs; 3) a solution to the problem of recruiting workers, since less people are willing to do repetitive work; 4) guaranteed precision and speed of the tasks, and durability; 5) improved workplace safety by reducing the occurrence of occupational accidents; and 6) improved competitiveness and quality of China’s manufacturing sector.

Government policies and financing

Government policies and financing

Since 2006, more than six Chinese state plans have set targets for China’s industrial robotics sector. The recent Made in China 2025 initiative is the most ambitious, aiming to comprehensively upgrade China’s manufacturing sector through the production and application of industrial robots. President Xi Jinping himself has said that the “robotics revolution” promised to become the “third Industrial Revolution,” and that people regard industrial robots as the “jewel in the crown of manufacturing”.[8] It is both high- and working-level support from China’s leaders, and targeted government planning, that is sustaining the demand for, and driving China’s own production of, robotics.

At the national level, in 2013, the Ministry of Industry and Information Technology released the Guidance on Promotion of Development of the Robot Industry to boost robot development. The guidance sets forth the objectives for the Chinese robot industry up to 2020. Featured policies include: attracting and assisting three to five world-leading robot companies to operate in China; developing eight to ten robot-related industrial fields; and promoting the application of robots to factories, outlining a robot population density of over 100 robots per 10,000 plant workers.[9]

At the local level, governments have set up investment funds and specialised capital to guide robotics innovation. In the coming the years, the Foshan Government plans to invest CNY 900 million in order to support the development of the robot industry.[10] It is also implementing a multi-layer supportive policy for machine-tool manufacturing enterprises. Furthermore, the Nanhai Park in Foshan founded the Robotics Industry Indigenous Innovation Supportive Sub-Fund in order to encourage enterprises to file for brand registration, formulate standards and to join exhibitions in groups. In 2015, an accumulated supportive fund of CNY 65 million was distributed to this sub-fund.[11]

China is also investing heavily in emerging technologies, such as artificial intelligence (AI) and nanotechnology, which can fundamentally change the capabilities of robot systems. Numerous finance and investment institutions are rightly keeping a close eye on the future of China’s robotics industry. Listed companies are being actively encouraged to participate in capital contribution or technology acquisition, and this is already taking place. Chinese state-owned conglomerates, companies and venture capital firms are all actively acquiring and investing in AI and foreign robotics technologies companies, particularly in Europe. While national plans seem to guide these acquisitions by prescribing which advanced technologies Chinese firms should acquire, it is the involvement of the finance sector that is considered the indispensable force that can transform China’s robotics industry from a follower to a frontrunner.

In order to provide funding assistance for the sustainable development of robotics companies, the Foshan Government has established a Robotics Mortgage Centre to attract funding. The Centre will gather qualified financing and leasing companies that can help companies to manage robotics installation projects through registering, financing and risk assessment. Additionally, subsidies will be available for companies using the mortgage service. This will allow factories to purchase robots through instalments while maintaining healthy liquidity.

Foshan Hi-tech Industrial Development Zone (FHIDZ), a national-level high-tech industrial development zone, was established with the approval of the State Council in December 1992. The FHIDZ is dedicated to building a “Golden Valley of Chinese Wisdom Manufacturing”. It has become the major engine for technological innovation and the industrial upgrading of Foshan City. It is also an important component of the PRD National Indigenous Innovation Pilot Zone, and has attracted 61 Global Fortune 500 related enterprises, 44 listed companies and 380 enterprises with an output value of more than CNY 100 million.

[1] http://money.cnn.com/2016/06/23/technology/china-industrial-robots/

[2] http://mt.sohu.com/20160804/n462521232.shtml

[3] http://mt.sohu.com/20160804/n462521232.shtml

[4] http://mt.sohu.com/20160804/n462521232.shtml

[5] http://www.fs-hitech.gov.cn/news/201610/t20161021_6177191.html

[6] http://www.fsonline.com.cn/2016/1019/226463.shtml

[7] http://www.fsonline.com.cn/2016/1019/226463.shtml

[8] J. Ray et al (2016), China’s Industrial and Military Robotics Development, Center for Intelligence Research and Analysis

[9] https://www.mizuhobank.com/service/global/cndb/economics/msif/pdf/R516-0002-XF-0105.pdf

[10] http://www.fs-hitech.gov.cn/news/201610/t20161021_6177191.html

[11] http://www.fs-hitech.gov.cn/news/201609/t20160919_6172631.html

Recent Comments