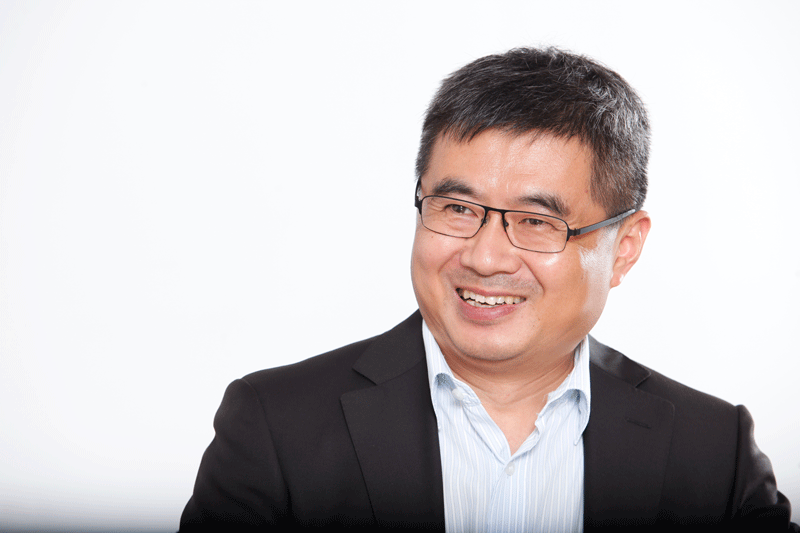

Interview with Dr Pan Huaiyu, General Manager, Siemens Shenzhen Magnetic Resonance Ltd

Dr Pan Huaiyu started his career with Siemens 14 years ago. He began working as an applied physicist in 2001, at Siemens Magnet Technology Ltd in Oxford, UK, before moving to Shenzhen in 2006 to take up a senior management post with Siemens Shenzhen Magnetic Resonance Ltd (SSMR). Dr Pan is also a board member of the Chamber’s South China Chapter. He speaks to EURObiz about China as a research and manufacturing base, and some of the challenges of operating in the medical devices industry.

Dr Pan Huaiyu started his career with Siemens 14 years ago. He began working as an applied physicist in 2001, at Siemens Magnet Technology Ltd in Oxford, UK, before moving to Shenzhen in 2006 to take up a senior management post with Siemens Shenzhen Magnetic Resonance Ltd (SSMR). Dr Pan is also a board member of the Chamber’s South China Chapter. He speaks to EURObiz about China as a research and manufacturing base, and some of the challenges of operating in the medical devices industry.

Why did Siemens select Shenzhen as its location when SSMR was established in 2002?

China held huge potential in the healthcare market, and it has gained even more importance to Siemens Healthcare over the years. There were a number of practical issues that were taken into consideration with the decision to locate to Shenzhen.

Shenzhen held, and still holds, the status of special economic zone, offering flexible policies and a favourable overall investment environment for foreign enterprises. It also has close proximity to Hong Kong, which is extremely convenient for import and export, and there is a great deal of existing industrial material resources for MRI production in Guangdong and the surrounding areas. Shenzhen also holds the advantage of having gathered an abundance of high-tech human resources.

Can you briefly explain what an MRI device is, including its application?

Magnetic resonance imaging is an advanced, non-invasive and extremely accurate medical imaging technology which can be used on all parts of the body. As MRI does not use ironizing radiation it is particularly valuable in the examination of chronic diseases that require repeated examinations. For many diagnostic issues, MRI has developed into the gold standard.

Apart from manufacturing, what other functions are carried out at SSMR?

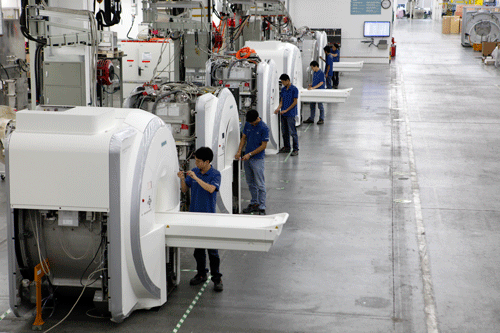

In addition to manufacturing, research and development (R&D), logistics, marketing, technical support and comprehensive services are all carried out under one roof.

In terms of Siemens global output, what is the percentage of MRI devices produced at SSMR?

One out of every three Siemens’ MRI systems has been delivered from SSMR since 2012. We serve customers in the Asia Pacific region, the west coast of the United States, South America and Africa.

Of these devices, how many are produced for the China market and how many are exported overseas?

Each year, over 70 per cent of SSMR’s products are exported to overseas users.

In terms of the China market, is there a clear difference in the numbers of MRI devices that are purchased by healthcare facilities in tier-one cities compared to those in tier-two or tier-three cities?

The purchase of MRI devices differs widely due to such factors as the level of hospital classification, its income and location, among others. In general, Class III hospitals[1] in tier-one cities, like Beijing or Shanghai, usually purchase at least two MRI systems for advanced diagnostics and treatment, and even research at the same time. For county-level public hospitals [Class II], they would typically buy one MRI or have none at all due to a lack of trained technicians.

Another trend we have observed is that more and more private hospitals are starting to purchase their first MRI systems.

What are the key criteria that guide purchasing of medical devices in healthcare facilities in China?

For hospitals that already have at least two MRI systems, they usually source high-end medical devices that can be utilised for advanced clinical applications and clinical research. The focus at county-level hospitals tends to be more on MRI devices that can satisfy their demand for routine clinical applications and patient throughput.

Are products manufactured at SSMR considered to be domestic or foreign?

Our products are considered Siemens’ MR products created in China. We are pursuing our strategic concept: ‘Created in China, For the World’.

In terms of manufacturing, the number of MRI devices produced each year is relatively low compared to, say, low-cost consumer products. Does this pose any challenges in terms of sourcing the raw materials and components required for production?

For certain materials that we use, such as superconducting wire and liquid helium, we do not really see any challenge – these materials are used in a number of other industrial applications and are therefore readily available. For other, specific mechanical materials there are certainly some challenges, but developing long-term strategic partnerships with international and domestic suppliers has helped in this respect. For the purchase of key MR components we have now established a full industrial value chain in China.

Are raw materials and components sourced in China or imported from overseas?

Both. Some strategic materials are purchased from large international enterprises, and we have developed local resources for other components and materials. Another important development was when a business line of Siemens Healthcare called CV—an internal supplier of electronic components and cabinets for MR systems—moved their R&D and production line from Germany to SSMR. This makes the transit of the components that they supply immeasurably easier.

Can you tell us about some of the innovations that have been developed at SSMR?

We place a lot of emphasis on developing local talent and strengthening the local R&D team in Shenzhen. This is bearing real fruit – so far more than 100 patents—both international and domestic—have been granted to SSMR. For us, it is important that SSMR develops MR products that are innovative and have excellent performance-price ratio. A good example is the MAGNETOM Spectra, which is the first 3T MRI system that has been both developed and manufactured in China. This is a breakthrough in the industry and is helping to ensure that the most advanced technology is available and accessible to hospitals in China.

Siemens Shenzhen Magnetic Resonance Ltd is the biggest research and manufacturing centre outside Siemens MR headquarters in Germany. It serves global customers with consolidating R&D, manufacturing, logistics, marketing, technical support and comprehensive services under one roof. SSMR has the full capacity for developing and manufacturing entire MRI systems and key components.

[1] Class III hospitals are large, public medical institutions with more than 500 beds, at the city, provincial or national level. They provide comprehensive healthcare services, and also carry medical education and scientific research; Class II hospitals are mostly in medium-sized cities, counties or districts and have between 100-500 beds. They also carry out some education and research on a provincial level; Class I hospitals are township hospitals with less than 100 beds. They perform preventative care and some other healthcare and rehabilitation services.

Recent Comments