Challenges for European companies in China

To better understand the research and development (R&D) world in China., what R&D entails needs to be defined. Quantifying how much research is being carried out in a company or a country is not easy; general statistics can provide, for example, how many engineers are involved, how much money the company/country is investing in R&D, but how many advanced projects are being developed and what kind or in which direction is not as evident. In addition, while research can spark several ideas, only some will go on to be developed, and of those few, only one or two will make it to the market, where they may or may not find success.

Therefore, the road to a successful project is long and difficult. Along the way, several issues may arise, such as others developing the same idea first and protecting it with patents, the team being infiltrated by a competitor, or collaboration with a university or another company being required to get to the next stage. Gianluca Giorgi, vice chair of the European Chamber South China Chapter, has summarised above the life path of an innovative project, explaining the difficulties of taking a concept to fruition.

China has many engineers skilled at developing products similar to others, but not so many can, or have the resources to, invent something original. This means that if you need to develop something similar to what you are already producing, Chinese engineers can quickly modify your solution and add many new features. The final product can be packed with accessories and functionalities; these may or may not be useful to the product’s/project’s purpose but will give added strength to the sales team’s pitch.

Previously in China, it was possible to recruit many engineers from a variety of fields and backgrounds because their salaries were lower than European researchers – w ho often cost at least double or three times more. Chinese engineers were more dedicated to their work, and benefitted from the abundance of examples around them for inspiration.

Nowadays, the situation is different: many engineers in China are now more costly and less productive than their European counterparts, giving several European companies reason to move their R&D activities—if not all, at least partly—back to Europe.

In addition, in the past, it was more profitable for China to produce, copy and learn from foreigners’ products because, first of all, if a product is sent for production in China, it meant the product was already accepted by the market, so copies or similar products are more likely to sell; and second, if a foreign company made that product, all potential problems will have already been weeded out and the final product will already comply with international safety and standardisation requirements.

The situation with R&D is different in Europe is different due a strong history of manufacturing development and innovation by companies and universities. There are also well-established frameworks for university-industry collaboration. This allows universities to test out theories by using a real project, though the process can take a long time due to the number of rounds of testing, networking with other universities/companies/institutions, and the lack of pressure to meet market demands within a fixed schedule.

Therefore, many European companies operating in China have a R&D department in Europe because there they can truly develop something new and innovate a full series of products. In China, they localise the project to suit the Chinese market. One major deterrence from creating R&D centres in China for European companies is the weak protection for intellectional property (IP) in the country. While the Chinese Government has made efforts to improve the IP protection system in recent years, it is still not on par with European levels. As a result, many European companies develop new products for the European market before moving them to the Chinese market or production lines.

Hurdles to collaboration

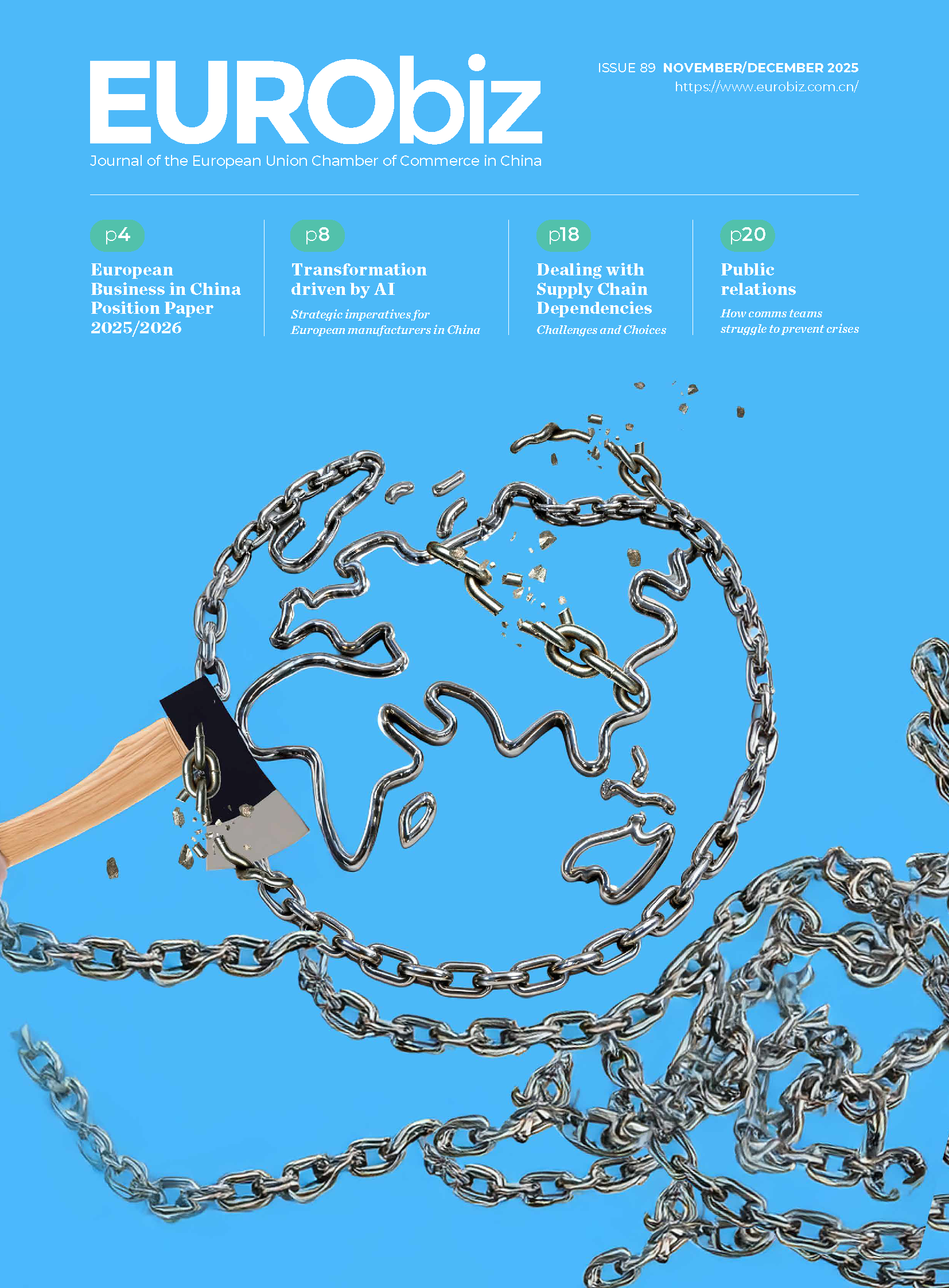

Another problem facing European companies with regard to R&D is access to materials, from electronic components to human tissue and organs. Up until the end of 2022, China’s strict zero-COVID policies had caused disruptions to supplies between Europe and China, leading to shortages in some components. This created many challenges for R&D teams, with uncertainty over their ability to source materials on time as well as the conditions for launching a product in the market. In addition, the United States (US) under the Trump Administation introduced onerous economic policies to protect its domestic market from Chinese products, which led to a US-China trade war that has also disrupted supply chains for new products. To top it all off, Putin started a war with Ukraine that is now affecting all sectors of the market, from materials and products to energy supplies. China’s ambiguous stance on the war has ruffled feathers in Europe and the US, and created challenges for R&D both in and outside China.

The increasing trend towards decoupling between the US and China means engineers often need to use different materials and components for different markets. In Italy, there is a phrase, “Between two faiths, the third will be the winner”, and indeed India has started to emerge strongly in the R&D area, as have several Southeast Asian countries like Vietnam and Malaysia.

While China has now ended its zero-COVID policy, many European companies have already moved some of their operations out of China, especially their R&D departments. The Chinese market remains important for European business but while China was the main target market pre-COVID, the recent supply chain and geopolitical difficulties mean that if a company does not have a strong presence in China, it will no longer be as profitable for it to have an R&D centre, or even a production base, in the country.

On the other hand, China is investing a lot in fields such as green energy and decarbonisation. European companies are in a strong position to support China on this front, though political issues may have a negative effect on these business and collaboration operations. It is necessary for China and the US, and all governments worldwide, to avoid friction and war. A stable and peaceful environment is vital for the global exchange of knowledge necessary to achieve the levels of innovation, development and decarbonisation required to save the planet for our children and future generations.

European Chamber recommendations

The European Chamber recently launched reports on standardisation, decarbonisation and innovation. These publications have been shared with Chinese stakeholders, including the Guangdong provincial and local governments with the aim of contribution to lifting the Greater Bay Area (GBA) to the next level. For example, when developing future technology, it is important for the products to comply with the relevant international standards for a wider impact and to avoid the waste of resources due to incompatibility. Decoupling of those standards would be counterproductive for industry development.

The European Chamber believes that high-technology manufacturing and new technologies are required to meet the growing demand for green energy and achieve both the EU’s and China’s decarbonisation goals. “Given that European companies have a strong track record of working towards carbon neutrality in their home markets, deepening EU-China cooperation in decarbonisation seems like a logical move.” In the South China Chapter’s viewpoint, in the GBA—particularly in Shenzhen—the business environment and infrastructure are poised to implement new technologies required for a green future.

The Chamber’s China’s Innovation Ecosystem reports show that some European companies are increasingly integrating China R&D with their global efforts and, while the majority are using China R&D to refine existing products, more and more are creating new goods and services in China that are included as part of their global portfolios. To maintain this confidence in the China market, it is vital to ensure equal access to government R&D support for all industries and companies, as well as a strong record on IP enforcement.

Gianluca Giorgi is a vice chair of the European Chamber South China Chapter and a member of the Information and Communications Technology Working Group. He is the chief executive of Shenzhen ES Automation Consulting Ltd, providing strategic mentoring in robotics and automation projects. Mr Giorgi also serves as the director of the Italian Innovative and Technologies Working Group, which belongs to the Italian Chamber of Commerce in China, created in partnership with the Italian Academic Association in China. Additionally, he is an MIT Sloan Blockchain Technologies: Business Innovation and Application Certified Expert, and member of the International Blockchain Council.

Recent Comments