How the chemical industry can play a sustainable role in China’s economy

The chemical industry has the potential to be a solution provider to many of the challenges faced by China, especially in the environmental realm. Steffan Huber, Senior Covestro Representative, Greater China, believes that by engaging in energy conservation, environmentally-friendly technologies and the manufacture of sustainable products, chemical companies can contribute to the advancement of China’s society and can help develop technological innovation in the long term.

The chemical industry has the potential to be a solution provider to many of the challenges faced by China, especially in the environmental realm. Steffan Huber, Senior Covestro Representative, Greater China, believes that by engaging in energy conservation, environmentally-friendly technologies and the manufacture of sustainable products, chemical companies can contribute to the advancement of China’s society and can help develop technological innovation in the long term.

China’s 13th Five-Year Plan (FYP) is expected to provide the framework that will allow the country to shift from an energy-guzzling economy towards a more sustainable model. The blueprint of China’s roadmap for the next five years—adopted during the Fifth Plenary Session of the 18th Communist Party of China Central Committee at the end of October 2015—indicates a thorough rethinking has taken place, ranging from energy to environment. Measures are expected to include ramping up the exploration of clean, safe energy resources to replace coal and other fossil fuels as well as more stringent enforcement of environmental standards in industrial production. To this end, the government has called for the establishment of novel distribution systems for the rights to use energy and resources that will enable businesses to better pursue their interests in benefiting the people, making a profit but not harming the planet. On the environmental front, Beijing is geared to widen the range of pollutants to be controlled and sharpen enforcement.

This will have huge implications on the environment and the local energy market. China is set to enter a crucial period where it will look to redress imbalances of past decades—with an emphasis on environmental degradation—and it will provide the opportunity to explore other government agendas such as encouraging innovation and improving the quality of life.

Challenges and opportunities

Chemical companies face increasing challenges as they are perceived as many of the causes of China’s safety and environmental problems. New investments in chemical facilities are more likely to encounter headwinds from the local population. After the Tianjin blasts in August 2015, a ‘not in my backyard’ mentality has become more prevalent, a challenge that is exacerbated by China’s rapid urbanisation, which may force the relocation of chemical plants to make way for expanding residential settlements.

But that is only one side of the story. What is frequently forgotten is that the chemical industry in China has over the past two decades also produced technological advancements that have addressed many of China’s challenges. Within the framework of the 13th FYP the chemical industry now has the chance to prove once again that it can be a solution provider, achieving better environmental protection and higher levels of sustainability. However, the entire industry must stringently act as one to overcome the current challenges—many of which are self-inflicted—to create a shared future and win public trust. To this end, all players have to start putting long-term viability ahead of short-term commercial gains, and unanimously adhere to standards and existing regulations. Stricter implementation of environmental protection laws and regulations serves the interests of China and ultimately benefits the chemical industry in the long term.

Multinational companies are often better placed to weather such adjustments and leverage sustainability due to their broader and longer-term experience. Increasingly, chemical companies recognise that sustainability has to play a key role in their global strategy, including in China. With the anticipated implications of the 13th FYP regarding safer and more environmentally-friendly production, upgrading of product quality and increasing sustainability, chemical companies will be expected more than ever before to adopt clean and safe production and to join hands with players across the value cycle to produce energy-efficient and emission-reducing solutions. Companies should strive to reduce the negative impact in all areas of the supply chain, production and logistics, and urge partners, suppliers and customers to adopt equally stringent measures.

A concerted effort

Over the past four decades or so, the chemical industry has been integral to the development of China’s economy. Chemical companies were some of the earliest investors in China. Today, state-owned enterprises, local players and multinational companies share the chemical industry landscape as their roles are converging. Multinational companies are increasingly becoming locally rooted while more local companies are branching out internationally.

Multinational chemical corporations, with their decades-long ‘clean-up’ experience, can help China’s overall industry raise standards through best practice sharing and dialogue. Their know-how in different aspects of chemical production, from efficient energy use and water utilisation in production, to safety standards and waste disposal, can be shared with or licensed to other chemical companies operating in China. Improvements of plants and the use of advanced energy-reducing or resource-saving technologies will help to improve production performance while at the same time reduce resource consumption and avoid waste generation and emissions.

Many chemical companies in China have started to recognise the importance of cleaner production as a business proposition. During the China Petroleum and Chemical International Conference (CPCIC) held in September 2015, some 430 Chinese chemical companies signed the Global Responsible Care Charter, formalising their commitment to responsible care, which represented a milestone in China’s journey towards sound chemicals production and management.

Chemicals as an enabler for sustainability

Chemicals as an enabler for sustainability

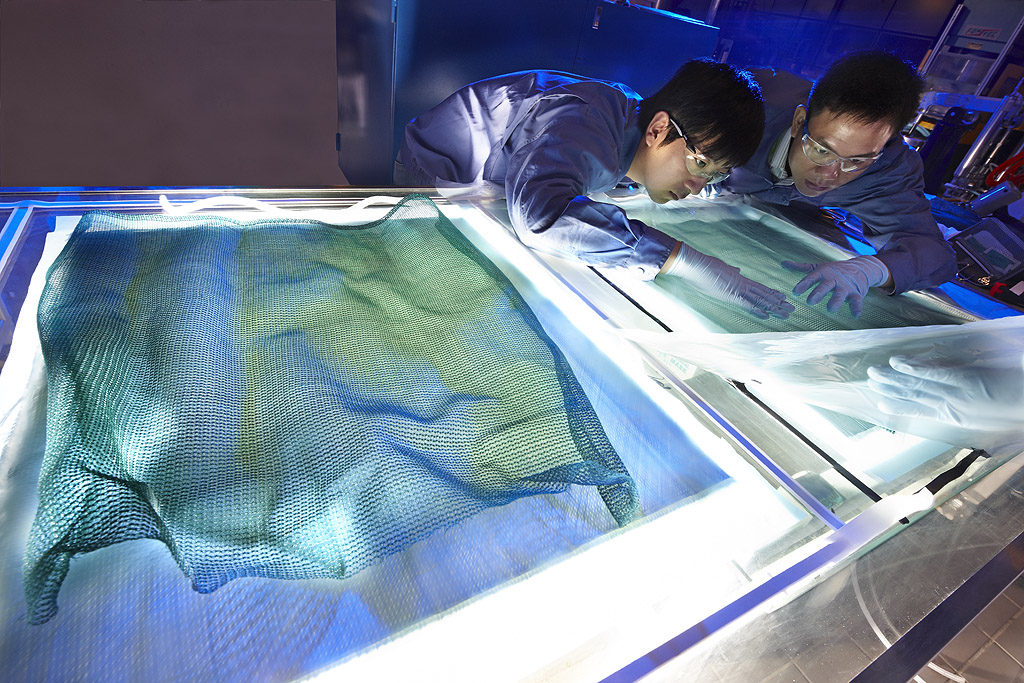

Sustainability as stipulated in the 13th FYP does not stop at improved production processes. It calls for higher quality products and consumer solutions. Here, chemicals and materials from sustainable production can play an even bigger role in enabling applications that improve energy saving or environmental protection. Below are some examples where materials are making a difference:

- Natural resources are being depleted, yet at the same time global energy demand shows no signs of waning. Technologies for renewable energy are an answer to this trend, for example wind energy. In China wind energy is already the third largest contributor of electrical power. To ensure maximum efficiency, modern windmills need ever larger rotor blades. They have to withstand the stresses felt in the atmosphere but at the same time need lightweight materials to reduce the mass of each blade. Materials such as polyurethanes can make a difference. Mixed with carbon fibre, these wind blades can reach up to a length of nearly 60 metres.

- China has already overtaken the United States as the world’s largest automotive market and millions more vehicles will hit the roads in the years to come. Vehicle discharge is one of the main culprits of the choking smog that frequently covers China’s cities and the government is looking at stricter emissions standards to curb pollution. By making vehicles as light as possible, less fuel is used and less exhaust is emitted for every kilometre spent on the road. Heavy metal parts are increasingly replaced by lighter parts for chassis, interiors or windows made from high-tech plastics such as polycarbonate. Such parts are also easier to produce than metal ones and they open up new design options, especially for electric vehicles.

- As the Chinese economy matures and moves towards a service-orientated model, structured urbanisation planning becomes more critical. The Chinese Government envisions resettlement of the population in cities in a safe and sustainable manner with an overall improvement in quality of life. This will include higher energy-efficiency targets for new buildings. One of the most important aspects for ensuring a building’s energy efficiency is good insulation: using superior spray foam polymers for parts of a building’s overall insulation system is a highly effective way of reducing energy consumption.

The chemical industry can undoubtedly play a significant role in the new Chinese economy, not only as the provider of sustainable solutions but also as the promoter and enabler of innovative approaches and R&D efforts. In the 13th FYP, China vows to embrace a sustainable development model by implementing a more exacting environmental protection system to actively control and reduce carbon emissions. By stringently focusing on addressing its challenges, China’s chemical industry has a chance to prove that it remains relevant to the country’s development through the creation of value for both the economy and society at large.

With 2014 sales of EUR 11.8 billion, Covestro is among the world’s largest polymer companies. Business activities are focused on the manufacture of high-tech polymer materials and the development of innovative solutions for products used in many areas of daily life. The main segments served are the automotive, electrical and electronics, construction and sports and leisure industries. Covestro, formerly Bayer MaterialScience, has 30 production sites worldwide and employs approximately 15,700 people (calculated as full-time equivalents) as of the end of September 2015.

With 2014 sales of EUR 11.8 billion, Covestro is among the world’s largest polymer companies. Business activities are focused on the manufacture of high-tech polymer materials and the development of innovative solutions for products used in many areas of daily life. The main segments served are the automotive, electrical and electronics, construction and sports and leisure industries. Covestro, formerly Bayer MaterialScience, has 30 production sites worldwide and employs approximately 15,700 people (calculated as full-time equivalents) as of the end of September 2015.

Recent Comments