A Chinese-European flagship program focused on creating climate solutions

A Chinese-European flagship program focused on creating climate solutions

Global warming has become one of the most pressing issues for countries around the world. Developing methods to mitigate humanities’ carbon footprint is of paramount importance and countries are tirelessly trying to craft solutions to do so. A new project called the Chinese-European Emission-Reducing Solutions Project (CHEERS), hopes to develop the crucial technology necessary to help mitigate global CO2 emissions and hopefully prevent Earth’s temperature from rising any higher. In this article, Mahdi Yazdanpanah and Zhonghua Xu, TOTAL, Nils Erland L. Haugen, SINTEF Energy AS, Stephane Bertholin, IFP Energies nouvelles (IFPEN), Zhenshan Li, Tsinghua University, and Suoshan Huo, Dongfang Boiler Group Co, Ltd (DBC), will explain why carbon capturing could be the solution to averting global warming disaster.

Carbon capture utilisation and storage (CCUS) is widely recognised as one of the best solutions to reduce the carbon footprint of industrial activities and mitigate global warming. This new technology can help the world meet the target of keeping global temperatures from rising above 2 °C by reducing the amount of CO2 emissions related to fossil fuel usage. The principle of this technology is relatively simple. Fossil fuels are normally exploited from underground reservoirs. It is then burned to produce energy, either to operate industries such as refining or to produce electricity. This combustion results in production of CO2 which is then emitted into the atmosphere. This innovative technology proposes an alternative way to capture the produced CO2 and return it back to its original place in an underground reservoir. Another possibility is to use the captured CO2 for production of other things, such as industrial chemicals.

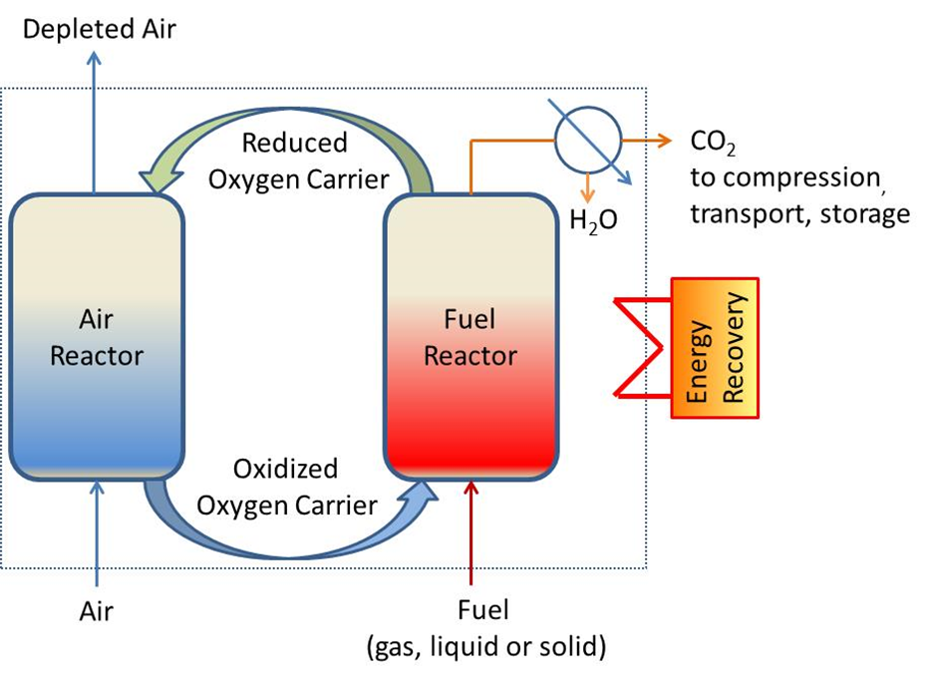

The foundation of CCUS is capturing the produced CO2 during combustion. This is the most expensive and complicated part of the CCUS chain. Today, there exists different technologies to capture CO2 like Chemical Looping Combustion (CLC). This is an innovative technology that has high energy efficiency and exerts a low cost for capturing carbon. As illustrated in the figure below, a metal oxide is used to transfer oxygen from the air reactor to the fuel reactor, where fuel is burned without direct contact with air. The resulting CO2 from the combustion part of the process is not diluted with nitrogen from the air, hence, no additional CO2 separation step is required. This is the main feature of the CLC process, which permits inherent CO2 separation with a high degree of energy efficiency.

Figure 1: Principle of CLC process.

Furthering this goal, CHEERS aims to demonstrate CLC technology on a semi-industrial scale for application in the petroleum refining industry. In addition to its primary scope, the applicability of CLC technology to the power industry will also be assessed with funding given from the Ministry of Science and Technology of the People’s Republic of China (MOST).

Both the refinery and power industries are key to reducing CO2 emissions. Utilising CLC technology can reduce the amount of CO2 emissions from a solid fuel combustion unit by achieving a carbon capture rate of up to 96 per cent. Additionally, the inherent CO2 separation in the CLC system permits high electrical efficiencies above 38 per cent (conventional steam cycle), which means that the CO2 energy penalty could be as low as four per cent. Comparing the performance of CLC with other available carbon capture technologies, CLC technology exhibits one of the most energy efficient methods at capturing carbon. This is a promising technology that can provide clean energy from solid fuels such as biomass, petroleum coke (petcoke) or coal. For example, a CLC unit with a 250 MWth feed using petcoke for refining applications will capture about 2000 ton/day of CO2. The avoided CO2 emission is equivalent to more than 700,000 cars.

The CHEERS project consists of nine partners, coordinated by SINTEF Energy Research. The consortium includes Tsinghua University (coordinator on the Chinese side of the project), Bellona, DBC, IFPEN, SINTEF Industry, TOTAL, Zhejiang University and Silesian University. This five-year project, funded primarily by EU Horizon 2020 and MOST, was started in October 2017 and a 3 MWth CLC plant will be installed on a DBC site in Deyang, China. This pilot plant should successfully achieve its operational goals and validate the developed CLC concept. It will also permit the evaluation of different technological and engineering challenges specific to CLC. Successful demonstration of CLC on this scale is a critical step towards implementing this as an industrial process.

The CHEERS project is comprised of several different work packages (WP), each with identified tasks. To oversee the coordination of this project, SINTEF Energy Research is responsible for overseeing logistics along with conducting lab testing and the large-scale production of oxygen carrier particles. With support from Tsinghua University, IFPEN is responsible for the work package in which the preliminary engineering design of the pilot plant will be carried out based on the concepts developed by IFPEN, TOTAL, Tsinghua University and DBC. The outcome of this will be a process design package that will form the basis for the pilot plant’s engineering study. This will be coordinated by TOTAL, with support from DBC, Tsinghua University, and IFPEN. In addition to the pilot plant’s design, a work package will be dedicated to the design and techno-economical evaluation of a full scale CLC plant for refining and electricity power generation. This work is coordinated by IFPEN. Tsinghua University is the coordinator of the work package that handles the construction, commissioning and start-up activities, including pilot operation. The Bellona Foundation, an international environmental non-governmental organisation, is coordinating the communication-related activities of the CHEERS project.

The CHEERS project is comprised of several different work packages (WP), each with identified tasks. To oversee the coordination of this project, SINTEF Energy Research is responsible for overseeing logistics along with conducting lab testing and the large-scale production of oxygen carrier particles. With support from Tsinghua University, IFPEN is responsible for the work package in which the preliminary engineering design of the pilot plant will be carried out based on the concepts developed by IFPEN, TOTAL, Tsinghua University and DBC. The outcome of this will be a process design package that will form the basis for the pilot plant’s engineering study. This will be coordinated by TOTAL, with support from DBC, Tsinghua University, and IFPEN. In addition to the pilot plant’s design, a work package will be dedicated to the design and techno-economical evaluation of a full scale CLC plant for refining and electricity power generation. This work is coordinated by IFPEN. Tsinghua University is the coordinator of the work package that handles the construction, commissioning and start-up activities, including pilot operation. The Bellona Foundation, an international environmental non-governmental organisation, is coordinating the communication-related activities of the CHEERS project.

In addition to the main CLC reactor system, related utilities and auxiliary systems will be demonstrated in the CHEERS project framework in order to ensure the readiness of CLC technology for industrial application. The final purpose of this project is to provide a high-quality captured CO2 stream for use in improving the production of petroleum in Enhanced Oil Recovery (EOR) applications.

The next step after the CHEERS project will be the industrial demonstration of CLC. This requires a: fully integrated CCUS chain, including CO2 capture by a CLC plant; treatment and compression of captured CO2; transportation of the captured CO2 at high pressure; and the injection of CO2 for EOR along with other applications.

For further detail about the CHEERS project and the role of different groups, the project can be found at http://cheers-clc.eu/.

Recent Comments