How to utilise the CRS system to achieve success in China

China has faced problems in robotics. There have been inconsistencies found between domestic policy and international standards. To better understand this industry issue, Xinhua Zhao, Vice General Manager of TÜV Rheinland Greater China Commercial Service, analyses current issues that face China’s robotics industry and helps to outline improvements to China’s robot certification system.

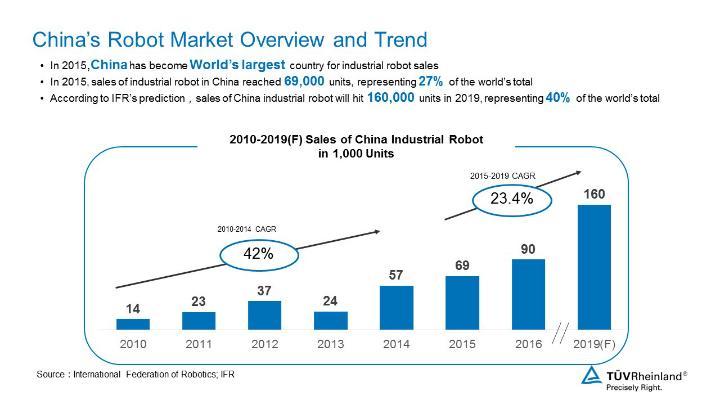

In recent years, under the influence of rapid market demand and national innovation policy, a large number of Chinese domestic companies have entered the research and development (R&D) and manufacturing areas of robotics. Since 2013, China has become the top seller of industrial robotics. In this booming industry, robot product quality and safety is increasingly being seen as an important consideration for factories. In order to ensure robot quality, the Chinese government has created its own robot certification system to standardise industry development.

The International Federation of Robotics has predicted in the next three years that China will dominate the

global industrial robotics market, with sales continuing to grow reaching 160,000 units and accounting for 40

per cent of global sales, in 2019.

The main problems in china’s robot industry

Despite notable progress in the robotics sector, China still faces a higher number of challenges compared to those faced in more developed countries. Key components need to be imported, and industry standards have yet to be regulated. Both problems constrain the sound and rapid development of the robotics industry.

1. Weak manufacturing capability of necessary components, results in a dependency on imported

goods

These imported components are essential for robot quality and performance. China has made some progress in robot R&D and is now capable of producing their own AC/DC servo motor and drive systems, photoelectric encoder, ball screw, hydraulic elements, and harmonic reducers. However, in general, China still has weak R&D and manufacturing capability, a low level of technology, and inferior performance in assembling key robotic components. This has begun limiting the development of China’s robotic industry.

Robotic components including the reducer, servo motor, actuator and controller account for approximately 70 per cent of the total cost for an articulated industrial robot. Currently, a large number of parts such as precision reducers, servo motors and actuators necessary for the production/integration of industrial robots in China have to be imported. This is especially the case for precision reducers and precision sensors with reliable performance, as few Chinese enterprises are capable of large-scale production of this product.

In 2015, approximately 75 per cent of all precision reducers were imported from Japan while over 80 per cent of servo motors and actuators were imported from either Japan, the United States (US) or Europe. Though some enterprises have successfully sought comparable local products, performance, stability, quality and reliability are yet to be generally seen during mass production. This problem, if it remains not dealt with, will prevent improvement in quality and performance of Chinese robots. More importantly, the high import costs of industrial robots will undermine the competitiveness of Chinese robot products and risk hollowing out the industry. If China can make breakthroughs as soon as possible in terms of key parts and components, the manufacturing cost of robots could be reduced by a large margin.

2. Industrial standards have yet to be regulated

To improve product quality, a set of agreed upon standards must exist. For a long time, the spotty quality and

reliability of robots has been a major bottleneck hindering development of China’s robot industry. One of the main reasons there has been a lack of product quality has been the absence of industrial standards. In China, robot industry standards are mainly formulated by adopting related international standards or assembled by Chinese standardisation commissions. Due to this, China did not, for a long time, have well-established standards for the robotics industry. Although the national standards refer to international standards, with some modifications, it still does not fully meet these requirements. In recent years, China has vigorously promoted the testing and certification of robots, which helps accelerate the establishing of a necessary Chinese robot standardisation organisation. With the formation of this organisation, a set of national robot standards, industrial standards and institutional standards could help build a sound set of robotic industry manufacturing standards. At the same time, creating a robust set of standards could help domestic criteria more closely represent existing international standards.

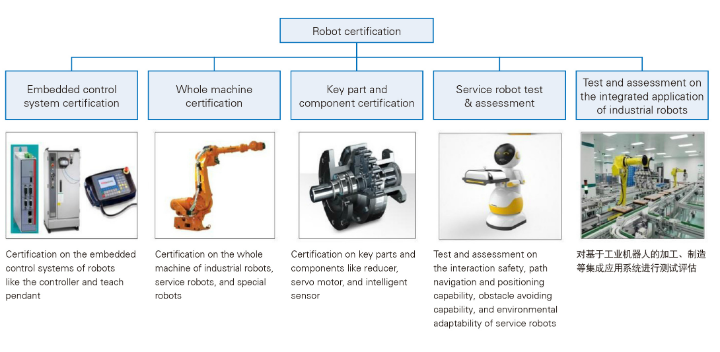

China robot certification

On 2nd November, 2016, the International Robot Testing and Certification Summit 2016 was held in Shanghai,

during which the National Development and Reform Commission, the General Administration of Quality Supervision, Inspection and Quarantine, the Ministry of Industry and Information Technology and the Certification and Accreditation Administration of the People’s Republic of China launched the China Robot Certification (CR) mark and issued the first batch of robot product certificates in China. This action marked the formal establishment of a robot testing and certification system in China.

In China, the industrial robot industry is now in the formation stage while the service robot industry is in its preliminaries. After the launch of China Manufacturing 2025, there will be increased demand in the manufacturing industry and an increased application of industrial robots and robot manufacturing used for producing high-precision products when human involvement in the production line is necessary, it is crucial to ensure the safe use of robots.

In accordance with the [2015] No. 360 Document of National Development and Reform Commission, i.e., the Notice of the Office of the National Development and Reform Commission on Issuing The Implementation Plan for the Industrialization of Key Industrial Robot Technologies, the National Robot Test and Assessment Centre (NRTAC) was established in early 2015 under the guidance of the National Development and Reform Commission, the Ministry of Industry and Information Technology, the Standardisation Administration of People’s Republic of China, the Certification and Accreditation Administration of People’s Republic of China, and China’s Robot Industry Alliance. The public service platform for robotic testing and inspection of the NRTAC, based in Beijing, is built and operated by the Research Centre for Computer and Microelectronics Development of MIIT (China Software Testing Centre or CSTC) and Beijing CCID Certificate Authority Co., Ltd. CCID Testing and Certification Centre Co., Ltd. is an enterprise under CSTC that serves as the platform for testing robotics. The public service platform for robot testing and inspection of the NRTAC is a third-party institution established by China that certifies, tests, calibrates, standardises, trains, and consults on robotic products and robot systems. The testing, certification, and standard formulation of robots is the bulk of the work currently. Certification is aimed at controlling the production quality through testing. The journey from testing to certification is appropriate for improving quality. The implementation of a robot test and certification scheme will help realise China Manufacturing 2025 targets that discuss robots with self-owned intellectual property rights.

Source: 2017 White Paper on Development of China’s Robot Industry

TÜV Rheinland is a global leader in independent inspection services, founded over 140 years ago. The group employs 19,300 people in 69 countries worldwide. Our independent experts stand for quality and safety for people, technology and the environment in nearly all aspects of life. TÜV Rheinland inspects technical equipment, products and services, and oversees projects and processes for companies. Our experts train people in a wide range of careers and industries. Our service scope includes industry and energy; transportation; machinery; electric and non-electric products; food; management systems; and training and consulting.

Recent Comments